As far as design is concerned, Nakanishi does everything from basic to detailed design and creates blueprints. Shipbuilding is based on design work using advanced IT technology. Since a ship is about the same size as a large-sized building in terms of the ship’s length, shipbuilding may well be considered to be a big project. A ship’s design may be classified into “basic design”, which has to do with the overall framework of the ship, and “detailed design”, which determines detailed processing methods for respective parts. For shipbuilding, construction planning and accuracy at the design stage, where even the slightest of errors are not allowed, are essential

From cutting ieon plates, welding, painting stool outfitting to finishing the ship, Nakanishi will be there every step along the way with you. Unlike the design stage, the construction process requires skilled craftsmanship. While mechanization and robotization are progressing at the processing and assembly stage of shipbuilding, manual work is still necessary for small parts. Nakanishi divides the hull into several blocks and builds the huge hull by dividing it into several processes such as “block making”, “block assembly”, and “stern outfitting”.

This is a process in which steel is cut with a plasma cutting machine. Accurate cutting based on blueprints is required.

This is a process in which the cut steel is assembled one by one. Detailed processing requires manual work.

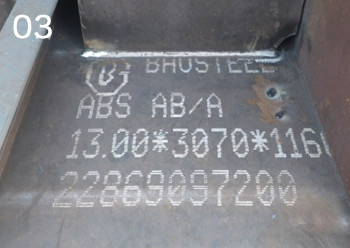

Building with materials approved for shipbuilding increases reliability of the ship and ensures quality.

When each part is completed, the block is picked up by a huge crane and the hull is assembled. This is where the hull can finally be seen.

Shot blasting is a process in which a motor is used to turn the wings and injects abrasives at a stretch to apply a surface treatment to the assembled material.

The huge hull is placed in a special booth and painted.

Assemble the completed hull block parts to complete the huge hull.

When the outer shape of the hull is completed, it will be placed in the dock and let float.

When the ship is completed on the stand, we let the ship slide across a slanted pedestal to allow it to enter water. Name for the ship is usually decided at this time, and this may be considered the moment when the ship is born. After the launching ceremony, with the ship anchored at the port, we will proceed with the installation of the fine parts, and the ship will be handed over to the shipowner when its performance and durability has been checked.